How to Setup MRP Module in ACTouch ERP?

Material Requirements planning (MRP) helps to manage the Demand and supply of items. It is one of the most advanced techniques used by manufacturing companies to manage their Supplier and Customers. We will discuss here about how to setup MRP modules in ACTouch ERP Software.

The major focus of manufacturing process is to convert raw materials to finished products based on Bills of materials and using production capacity of machines and using human resources. Cost of raw materials / inventory costs with production costs and Human Resource costs will give the Finished Products costs and this process called ABC – Activity Based Costing.

Scheduling production with inventory management and master production schedule with machine capacity planning helps to improve outputs.

Typical demand in manufacturing companies are created by

- Confirmed Customer demands / Sales forecast.

- Product forecasting or historical sales or Forecast Demand.

- Items that are below REORDER Level that have gone below inventory level / safety stock level.

- Work orders that are created manually as a demand to produce. Manufacturing resource planning with master production scheduling helps to improve manufacturing production and it automates process. It helps to reduce the errors and improves efficiency with a decent stock levels for Production management.

Calculation of material requirements considers the below conditions to arrive at the stocks and how much to demand. Since MRPs use the “Backward scheduling” process, it decides the demand based on the Due date on which the Finished Goods to be delivered.

- Material availability / Available Stock (This is excluding the Raw Materials / Semi -FG / FG in Blocked conditions or issued for a production work)

- Open Purchase Orders where the Raw materials could be received by a due date

- Confirmed Work Order (Production orders)

- Bill of Materials with Production process and master production schedule from customer, if any

- Pre and Post Machine Loading with each components processing time needed to arrive at the total timelines for production plan with material planning

One of the good features of MRP is, it also gives alerts on those Purchase indents that are not converted to Purchase Orders.

Please click here to read more of Material Requirements Planning –

How to Setup MRP Module in ACTouch ERP?

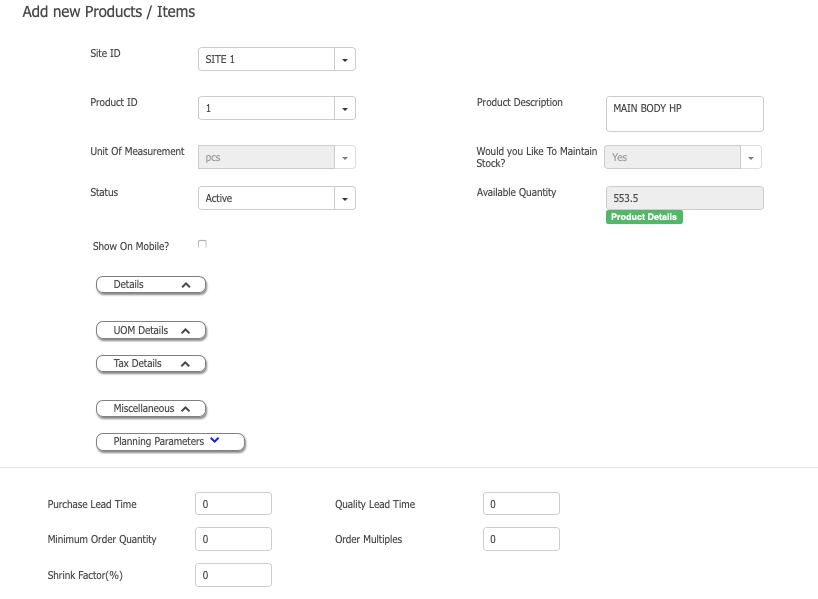

Step 1: Configure the Products with Planning parameters.

Go to Product master (Home -> Master settings -> Product Master) and open the product that needs to be considered for the Planning cycle.

There are multiple types of items we consider as this defines the time required for the

- Manufacturing

- Purchase

- Assembly items

Now based on the type of the ITEMS whether its MANUFACTUERED or PURCHASED, please select the right parameters.

- Purchase / Manufacturing Lead time – its in Days. Number of days required to Manufacture or Procure the materials

- Minimum Order Quantity – Many times, we need to Place a minimum quantity with Supplier or ensure to store the same in the company.

- Quality Lead time – Number of days its required to do the quality check and release it to production.

- Order Multiples – Its an interesting parameter. For example, you need Cement and its normally sold in 50KG bags. If you need 22KG, but based on the Order Multiple, MRP would place the order as 50KG.

- Shrink factor – Typically used in Oil, Diesel etc. as item would be evaporated due to Sun while travel. So ensure that we don’t get less than what is planned.

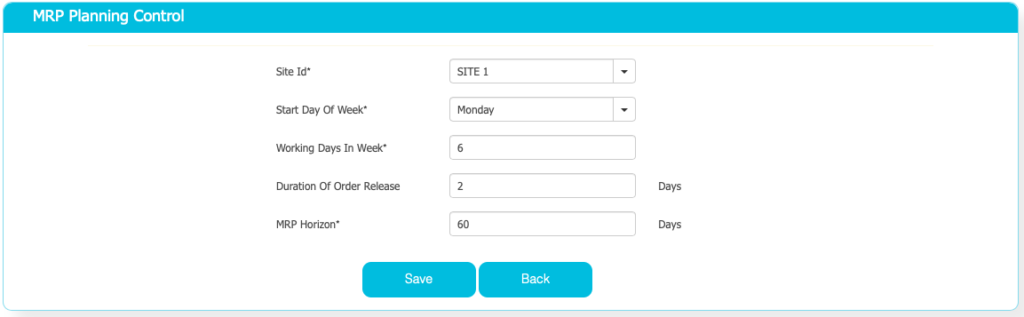

Step2: Configure MRP Module with its Control File

Once the product master is ready, now configure the Control File

- Working days in a week, helps to inform Planning module on the working days in a week

- Duration of Order Release – This helps to give an additional days before the order is placed to Supplier or Production. Typically, it takes 2 days to approve Purchase Order and release to Vendor. So we should plan the same

- MRP Horizon – This helps MRP to see the demand from Today till how many days. For an example, we have the demands for next 6 months and marketing has confirmed the demand forecast for 6 months. But from company Cash-flow and manage the inventory etc, it doesn’t makes sense to plan any items more than 30 days. So you can ask the MRP to plan for the demands for the next 30 days.

Now you are ready to run MRP and see the results.

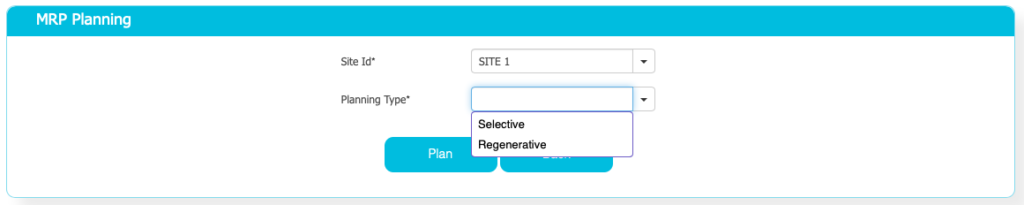

Step 3: Now Run MRP Module in MRP System based on your business needs.

While running an MRP, you get 2 options.

- Regenerative MRP

- Selective MRP

Typically, Manufacturing companies run REGENERATIVE MRP at the beginning of the month, such that we get the overall demands for the month and reschedule all the missed demands.

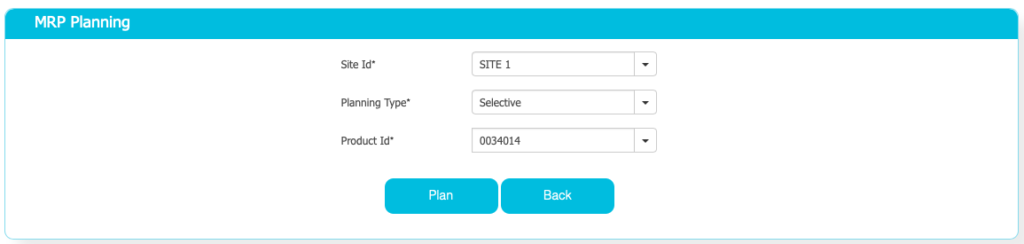

Selective MRP is used when you have received a demand for an ITEM and you want to see the demands only for this and not to disturb the remaining items that are already in production. Here you get an option to select that specific item

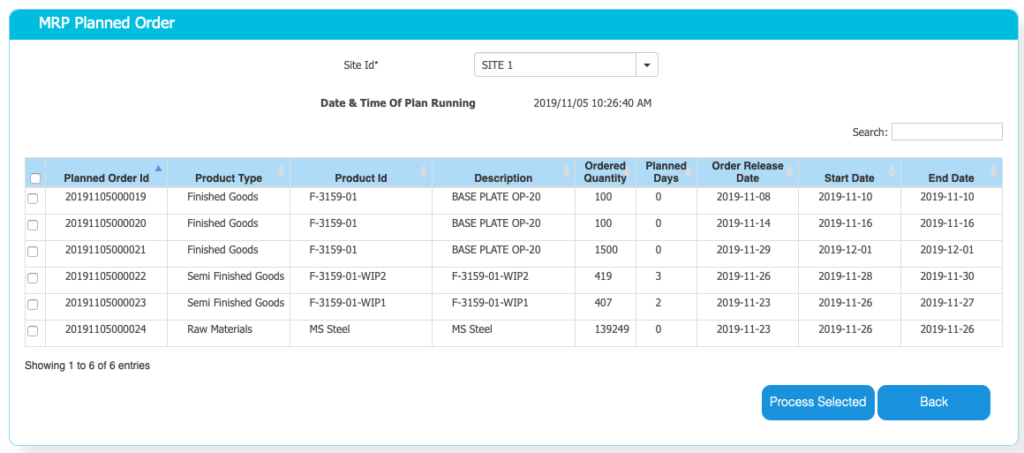

Once you run MRP, you will get the details of Planned Orders and Work Orders as below. MRP normally releases the PLANNED orders and not a CONFIRMED order. Production Planning and Control (PPC) department normally confirms the orders and releases for Purchase or Productions.

|