Inward Delivery challan (IDC) for Subcontractor

Subcontracting IDC or Inward Delivery Challan helps to receive the Finished Goods against which the RM were sent to him. ACTouch ERP connects the Outward Delivery Challans (ODC) that are sent to the Subcontractor and we receive the FG against the same.

This is done to connect the each ODC to IDC and ensure that sent materials are accounted 100%.

During the creation of IDC, following work happens automatically.

- Receive FG from Subcontractor. You can also receive more than one FG.

- Connect the RMs that is consumed to manufacture the FG. This helps to reduce the stock that’s sent to Subcontractor.

- You can also report the receipt of By-products that are to be accounted. For example – Scrap materials, Casting metal scraps etc.

- If any remaining materials are received, then we can also receive the RMs back to our inventory.

- When we receive the materials. We have an option to add the service costs to FG and this create a Goods Receipt note automatically and also helps to pay the subcontractor for the work he did.

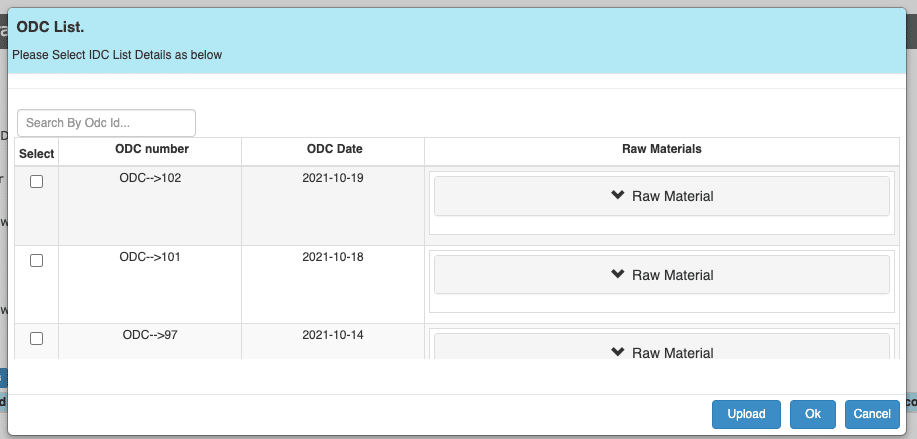

Once you select a Subcontractor ID, application will pop-up all the OPEN ODCs that are yet to received. Based on the selection of a ODC or multiple ODCs, you can create an IDC now.

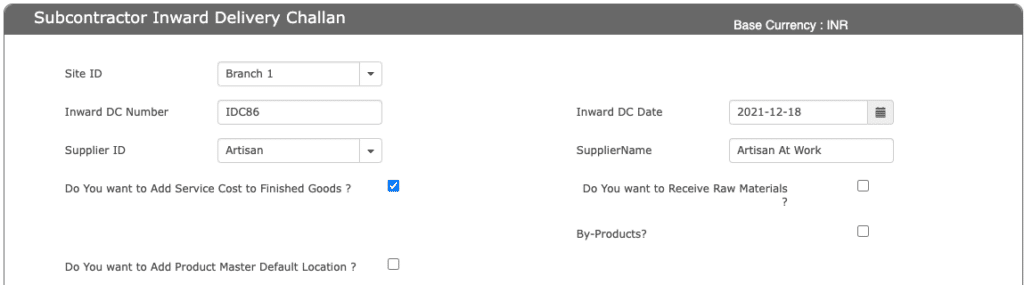

IDC Entry Screen – Important fields and how they work?

Here you can enter the necessary fields. Important are

- Do you want to add Service Costs to Finished Goods = Yes / No – Helps to add the service costs to RM costs and add to Finished Goods. This creates the Purchase Receipt to book the product costs.

- Do You want to receive Raw Materials – Yes / No – In few cases, we also receive back the RM sent to vendor. So this field helps us to receive back the RM and doesn’t bill vendor.

- If you select the above = YES, then you need to mention the “LOCATION ID” where the RM comes back.

- “Do you want to ADD PRODUCT MASTER DEFAULT LOCATION” – If you want the RM should be returned to default location defined at Product Master level, then choose this field.

- By-Products – Yes / No – This helps to receive the By-products that are formed due to the RM conversion to FG level. Like Scrap materials, Brass cut pieces etc

Once you select a VENDOR, application will pop-up the below SCREEN to LIST all the OPEN DELIVERY CHALLANS thats sent to Vendor.

We have the option to select an ODC or multiple ODC’s to receive the FGs and it will list the RMs thats to be consumed.

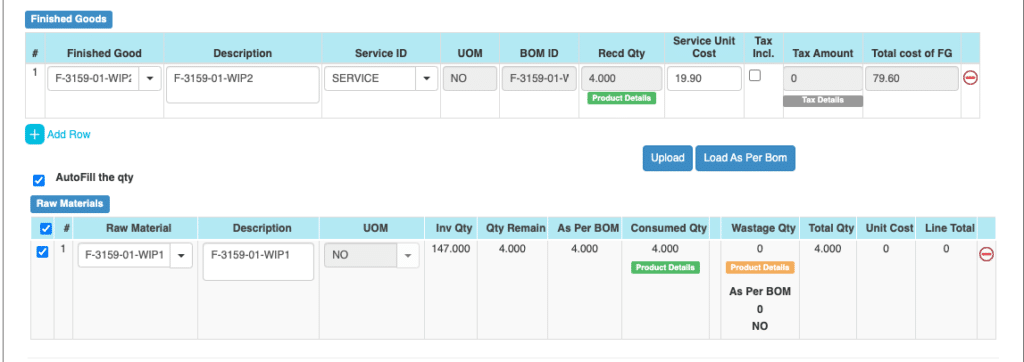

IDC Field details are as below

| No | Field ID | Field name | mandatory | Field description and how it helps? |

|---|---|---|---|---|

| 1. | IDC Number | Inward Delivery Challan Number | Yes | ERP automatically created an Inward Delivery Challan number for the materials that we receive from the customers. You can also enter the ID manually. |

| 2. | Supplier ID | Subcontractor ID | Yes | It gives the specific number for identification of each subcontractor. |

| 3. | Supplier Name | Subcontractor Name | Yes | Name of the Subcontractor who is doing the Job work. |

| 4. | Do You want to Add Service Cost to Finished Goods? | Yes /No | Yes | This helps to add the RM and Services costs to the FG that’s reported now. |

| 5. | Do You want to Receive Raw Materials? | Raw material returns | No | It gives us an option to select if we want to receive any RM that are remaining at vendor place. We bring back all the items including damaged ones. We need to receive all the materials to close the ODC else it will remain OPEN. |

| 6. | Location to Receive | Location where we receive the RM from vendor | Yes | Location where we receive the RM from vendor |

| Default Location | Yes / NO | No | It helps to receive back the RM back to their default Locations. | |

| 7. | By-Products | By-products that we are receiving | Yes | Its gives an option to select if any By-Product is produced while working on the raw material. This helps to inventorise these products. |

| 8. | Finished Goods | Finished Goods ID | Yes | It is the end product produced for delivery to the customer. |

| 9. | Description | Finished Goods Description | Yes | FG Description. |

| 10. | Service ID | Service provided | Yes | It gives us what kind of service is being provided by vendor and for which we need to pay him. |

| 11. | UOM | Unit of measurements | Yes | Unit of measurements |

| 12. | BOM | BOM identification number | Yes | It is the unique identification number given to each bill of Material. |

| 13. | Recd Qty | Received quantity | Yes | It gives the received FG Quantity by the Subcontractor |

| 14. | Service Unit Cost | Cost of service/ Unit | Yes | Its gives the cost of service for producing one unit of the Finished Good. |

| 15. | Tax Incl. | Tax Inclusive | No | It gives an option to include the tax amount on the Finished Good to the Contractor. |

| 16. | Tax Amount | Total tax amount | Yes | It is the total tax amount levied on producing the Finished Good. |

| 17. | Total cost of FG | Total cost of the Finished Good | Yes | This gives the total cost for the job work done for producing the Finished Good. It includes RM costs and Services costs paid to the contractor. |

| 18. | Raw material | Raw material ID | Yes | RM ID that’s consumed. |

| 19. | RM Description | RM Description | Yes | RM Name and description. |

| 20. | UOM | Unit of measurement | Yes | UOM of RMs |

| 21. | Quantity Consumed | Inventory Quantity consumed | Yes | It gives the total quantity of any specified raw material in the inventory. |

| 22 | Location | Location ID | Yes | You can choose the Quantity consumed from a specific ODC and its vendor location. Here you need to connect the consumption of RM to the specific FG IDs. |

| 23. | Wastage in % | Percentage Wastage of the raw material | Yes | It gives the total percentage of the wastage of the raw material while producing the finished good. |

| 24. | Wastage Qty | Quantity of wastage | Yes | Total amount of wastage accrued while producing the finished good. This is as mentioned in the Bill of Materials. |

| 25. | Total Qty | Total quantity of the raw material used. | Yes | It gives the total quantity of the raw material used to develop a finished good. |

| 26. | Unit Price | Price of a single unit of RM | Yes | It gives the price of one single unit of the raw material used for making a finished good. |

| 27. | Line Total | Total price of the raw material used | Yes | It gives the total amount of the particular raw material used.Total Qty*Unit Price = Line Total |

| 28. | By Product ID | By-Product ID | No | It is the unique identification number given to the By-products obtained while making a finished good. |

| 29. | Description | By-product description | No | It describes what By-product we get while converting the raw material to finished product. |

| 30. | Quantity in % | By-product quantity in percentage | No | It gives us the percentage of By-product produced while producing the finished good. If this is field is not selected then we will be directly taking the magnitude of quantity of the by-product into consideration ignoring the percentage quantity of the by-product. |

| 31. | Percentage | Percentage of the quantity | No | It gives what percentage of the quantity is assigned to the by-product. |

| 32. | Quantity | Quantity of the by-product | No | It gives the total magnitude of quantity of the by-product we get after calculation of percentage of the quantity. |

| 33. | Cost Allocation in % | Allocation of cost in percentage | No | The total amount allocated for the by-product in percentage value.If this field is not selected then we directly take the magnitude of the cost allocated for the by-product. |

| 34. | Amount | Total cost in amount of the By-product/Scrap | No | It gives the total cost of the scrap in amount / percentage. If the cost allocation in % field is selected then we will get the cost in percentage otherwise we get the cost in amount. |

| 35. | Cost of By-product | Total cost of the By-product | No | Its gives the total cost of the By-product /Scrap generated in the process. |

| 36. | Shipping Mode | Mode of Delivery | No | It gives the transportation mode by which the Finished Good, Raw Materials Return, By-product/Scrap will be delivered to the destination.Ex: By Air, Cargo etc. |

| 37. | Vehicle courier details | Vehicle /courier details | No | This describes the vehicle and courier details such as transporter name, courier name, vehicle number, etc. |

| 38. | Gate pass Id | Gate pass identification detail | No | This gives the Company Inward Gate pass id |

| 39. | Gate pass Date | Gate Pass Date | No | When we received the material at our factory. |

| 40. | Transporter Name | Transport Organization Name | No | This is the name of the organization which is responsible for transporting the Finished Good, Raw Materials Return, By-product/Scrap. |

| 41. | Transporter GSTN | Transporter Tax ID | No | This gives Transporter TAX NO. It’s a unique ID necessary for businesses. |

| 42. | Vehicle No. | Transporter Vehicle Number | No | This gives the Transporter Vehicle Number which transports the Finished Good, Raw Materials Return, By-product/Scrap to the Contractor. |

| 43. | Courier Name | Courier Agency Name | No | This is the Courier Agency Name responsible for delivering the Finished Good, Raw Materials Return, By-product/Scrap to the Contractor. |

| 44. | Courier Branch | Courier Agencies Branch Name | No | This gives the Courier Agencies Branch which is responsible for delivering the Finished Good, Raw Materials Return, By-product/Scrap. |

| 45. | Courier Date | Date of product dispatch | No | This gives the date on which the Finished Good, Raw Materials Return, By-product/Scrap was dispatched. |

| 46. | Docket Number | Vehicle registration number | No | This gives the vehicle registration number of the transporting vehicle. |

| 47. | GC / LR Date / Ship Bill Date | Receipt of the lorry | No | It is the receipt of the date that specifies the landing date and it’s the receipt that we receive from the transporter. |

| 48. | GC / LR Number / Ship Bill Number | Lorry receipt number | No | This gives the lorry receipt from the transporting company. |

| 49. | Packing Date | Date of package | No | This tells us the date the Finished Good, Raw Materials Return, By-product/Scrapwas packaged. |

| 50. | Packing Number | Product package number | No | This gives the number allotted for the package. |

| 51. | Number of Packages | Total number of package | No | This gives the total number of packages to be delivered. |

| 52. | Weight of Packages | Total weight of the packages | No | This gives the total weight of the packages to be delivered. |

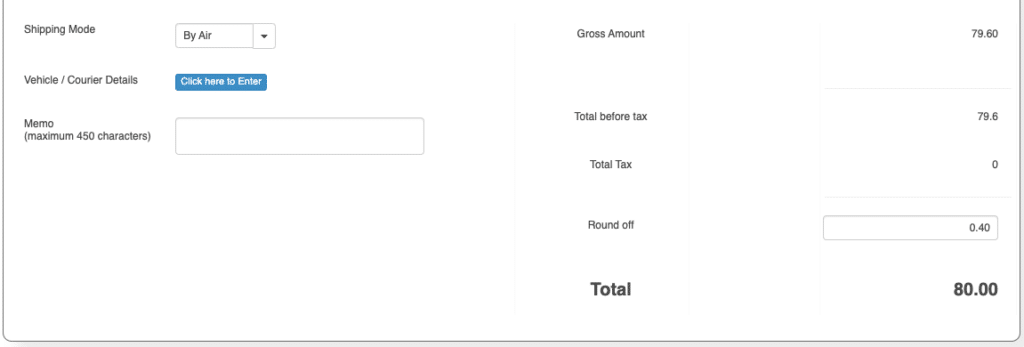

IDC Summary portion where the total Amount of materials that booked by Application is shown

| 62. | Memo | Memo | No | Any other specific information to capture? |

| 63. | Gross Amount | Gross Amount | Yes | It is the total amount of the Finished Good that is delivered to the Contractor. |

| 64. | Total before tax | Amount before tax | Yes | It provides us the information of the total amount before Applying tax. |

| 65. | Total tax | Tax amount | Yes | It tells us how much total tax has been levied on the gross amount i.e., tax on the gross amount. |

| 66. | Round off | Rounded off amount | Yes | It gives the Order Amount in natural numbers or non-decimal numbers. |

| 67. | Net Amount | Total Amount of the Order | Yes | It describes about the total Order amount after rounding off. |