Product master / Items master are an important Parameter to define for the ERP to work. So we need to create Product or Item Master required for the following business needs.

- Identify the inventory values in the company that you hold

- This links the Inventory AMOUNT that reflects back on the Balance Sheet as “Assets owned by Company”

- It helps to create Sales Orders, Purchase Orders, Bill of Materials and Production Reporting etc.

In ACTouch ERP, we define the following products as part of PRODUCT Master. We don’t have other menus to define the below items SEPARATELY like some other ERP’s.

- Raw Materials

- Semi Finished Goods

- Finished Goods

- Other Materials like TOOLS, Equipment etc.

Is it Mandatory = Yes.

It is mandatory data for the Traders and Manufacturing companies who wants to keep and track Inventory.

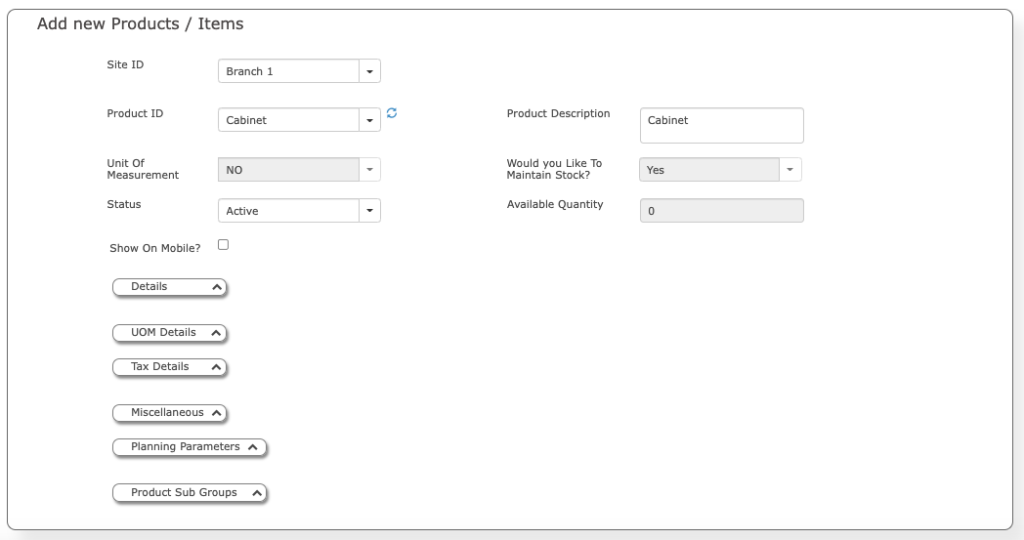

Few Important Parameters to be aware of while creating a Product Master in ACTouch ERP are as below.

Product ID is a unique Record and its cant be CHANGED once you create them. The same is for the Units Of Measurement (UOM)

A product defined as “Inventory” or “NON-Inventory” based on the business need

Inventory – “Yes” – This makes sure to keep the stocks and Unit Cost of the Materials

Inventory – “No” – This type of setting is good for the “Expenses items” that are NOT KEPT inventory in your Organisation.

You can also create the SERVICEs items as part of this process like “Servicing”, “Molding”, “Fabrication” etc.

Basic Parameters Settings for Create Product master

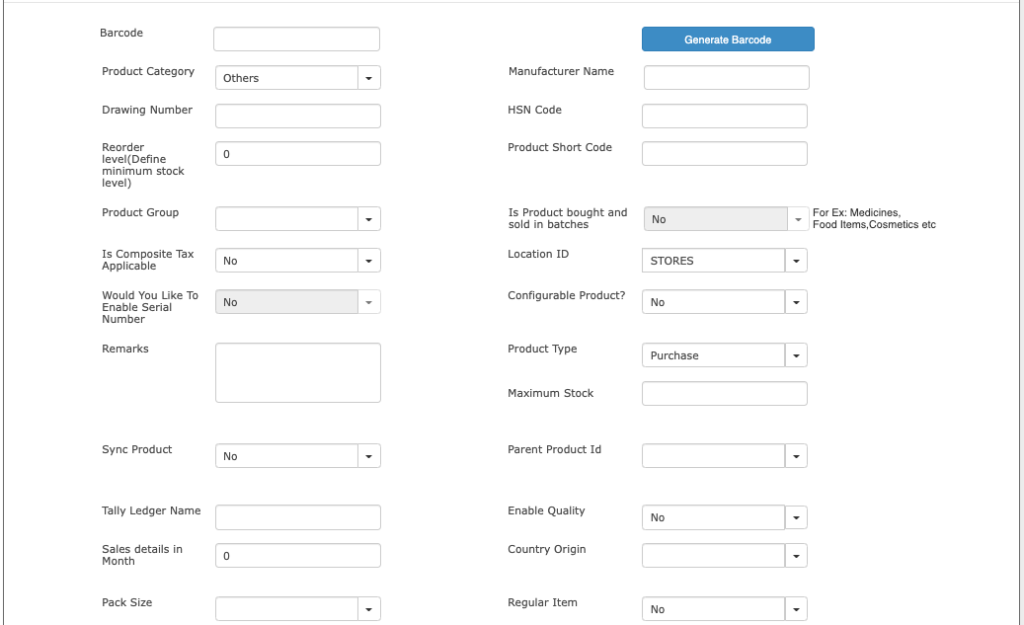

Batch Items –“Yes / NO”

Few Raw Materials or Finished Goods that we purchase like Chemicals can have a Batch NO and its Expiry Dates to track their Purchase, Where they are used as part of another product etc.

Serial No = Yes /No

Few Raw Materials that we procure or Finished Goods that we sell will have a specific SERIAL NO to track those products. For example – Mobile Phones, CNC Machines and Vertical Milling Machines etc

Product Type

You can choose a Product as “Purchase”, “Manufacture” as it indicates and informs the ERP that these are Purchased or Manufactured items. Based on this, the application will run the Planning Modules and need to fill few values.

Location ID – The default Location where the Stocks are kept. You can create multiple Location IDs and attach each Product to ONE location. Helps in picking the items for the dispatch etc.

Product Group – You choose the right Product group that this Items belongs. You can also choose the SubGroup1, SubGroup2 or SubGroup3 etc. For Product Group click here.

Enable Quality – We have integrated the Quality Module with our ERP software and its connected to each Product. You have the option to decide whether this items needs to be Pass through Quality Module or not.

When you receive this material, against a GRN or finished goods reporting, those DOCUMENTs would appear on Quality Dashboard to process the test cases.

Country of Origin –Mainly for the identification of Product for Govt purpose.

Tally Ledger Name – This helps to pass this Product name into whats called in Tally ERP9 Software.

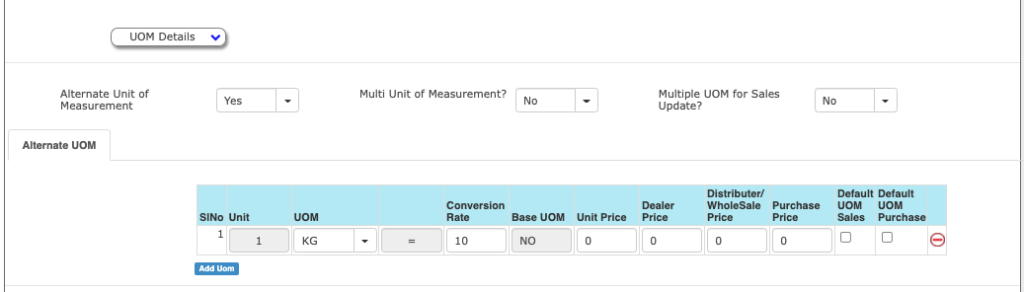

Alternate Units of Measurements

For example- Chemical items, Food Items etc.

Units of Measurement – This helps to define an ALTERNATE UOM or MULTI UNITS of MEASURMENT for the SAME Product. Please note these are DEFINED and are SPECIFIC to this PRODUCT only.

For example – Product “SPINDLE” is kept in “NOS” for Inventory purpose. But I can sell the same in KGs too.

So, we can define an Alternate UOM as = 1 KG = 15 Nos.

Multi Units of Measurement – A special design to handle the SHEET materials type of products where we keep the stock n 2 Unit of Measurements.

For example – 2 mm Sheet is KEPT in “KG” in system and also used in “NO”s for production purpose. The advantage is the same item can be kept in MULTIPLE KGs too.

So we can define the conditions like

2mm Metal Sheet = 10 No @ 15 KG per sheet = total Weight is 150 KG

2mm Metal Sheet = 4 No @ 16 KG per sheet = total Weight is 64 KG

This means, we have 14 NO of 2 mm SHEETS with total WEIGHT of 214 KGs

Good for Sheet Metal and Stamping Industries, Steel Rods manufacturers, Packaging Industries, Wood Industries etc

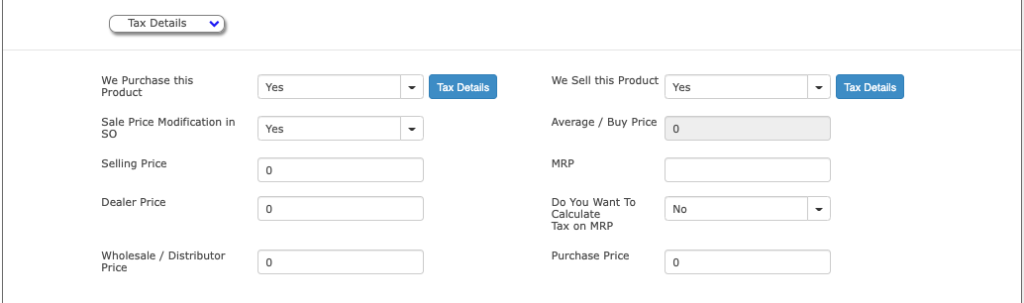

Taxes and Unit Price details

We purchase this Product / We sell this Product = This helps to display these items in Purchase or Sales Time.

Average / Buy Price – This is the UNIT COST of the Products that’s updated by GRN or FGR or Inward DC etc. We don’t allow modifying this price as it has connection to financial balances

Tax Details (Purchase / Sales) – Here you can attach the DEFAULT TAX CODES for this product when you Sell or Purchase.

Selling Price – for the Normal Customers price

Dealer Price – Based on the CUSTOMER TYPE = “Dealer”, this Selling Price appears in Sales Order or Invoice.

Wholesales / Distributor Price – Based on the CUSTOMER TYPE = “Wholesaler / Distributor”, this Selling Price appears in Sales Order or Invoice.

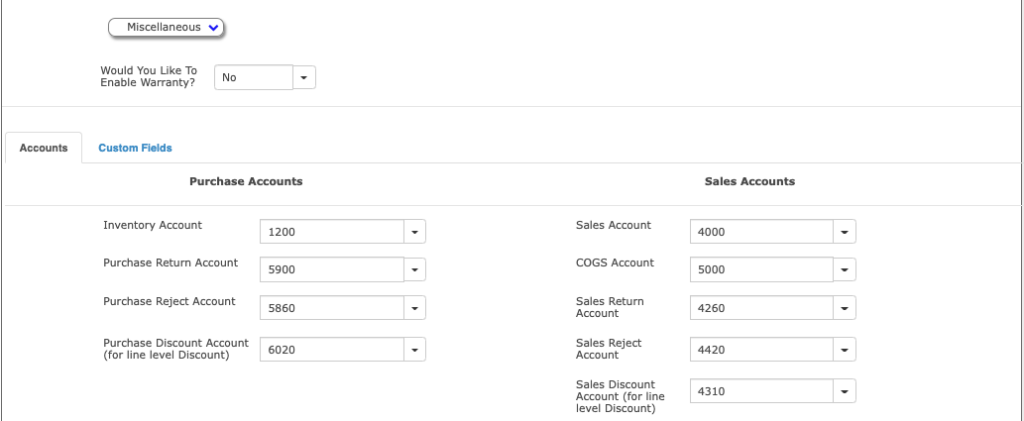

Accounts that are associated with this Product

Accounts

There are many accounting entries we pass as part of the transactions. However 2 accounts are important. Click here to know more

It’s best to leave these accounts as it is, unless you want to show the values on Balance sheet and Sales Accounts separately.

For example,

- You want to SHOW the RM or FG Values in Balance Sheet separately. – Change the Inventory Account for each Product group.

- If you want to SHOW the SALES that happen by EACH COMPANY (Say, Reliance or TATA etc), then change the PRODUCT SALES ACCOUNT to these GROUP Accounts to show the SALES FIGURES for these items.

Account Details.

- Inventory Account – The total INVENTORY Value of this Product will appear on balance sheet through this account.

- Sales Account – The total Sales value of this Product will appear on Profit and Loss sheet through this account.

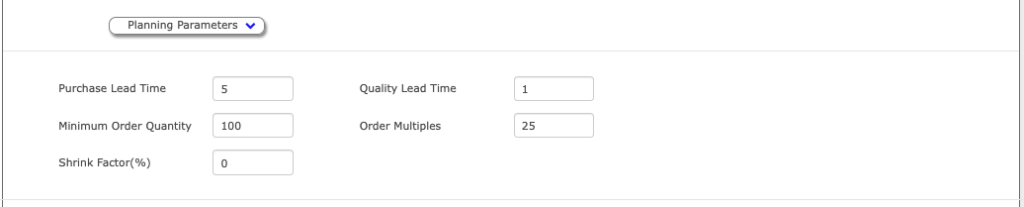

Product Planning Parameters

Planning Parameters

Few important parameters are as below. You can refer to “MRP” document for more.

- Purchase Lead time

- Manufacturing Lead time

- Quality lead Time.

- Order Multiple

- Minimum Order Quantity