How to create Work Orders?

Work Order as the name suggests it’s the Order given to the Production department to work on. It contains the major information like

- Work Order ID

- Date of the document

- What Product to produce, its Quantity and Units.

- Steps to Follow.

- Each step, what product is expected.

One of the advantages of ACTouch ERP is that to complete a Work Order, you don’t need to move around different menus like Shop floor control, Subcontracting Operations, Reports Finished Goods etc.

You can do the majority of work like

- Request for the materials from Stores. (Material Request form)

- Report FG Reporting. (FGR Process)

- Create Outward Delivery Challan (ODC) and send the same to Supplier.

- Do the Inward Delivery Challan (IDC) and report the Finished Goods and move it to next steps.

- Update the Work Order to report the rework of the same Finished Goods.

- Close the Work Order, in case it’s of not used any more.

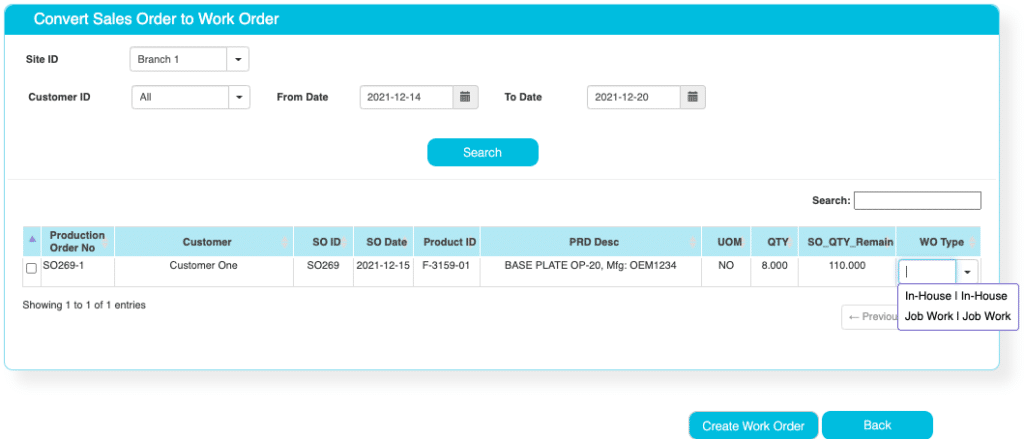

Video on how to Convert a Sales Order to Manufacturing WORK ORDER? With Operations, Work Center and define Routings.

Steps to follow is as below to create WORK ORDER.

- When you create the Work Orders manually, select the ROUTING that suits for that WORK ORDER and for that FG.

- Based on the ROUTING ID, the process are added to the Work Order. You can still delete those Process steps and add your own too.

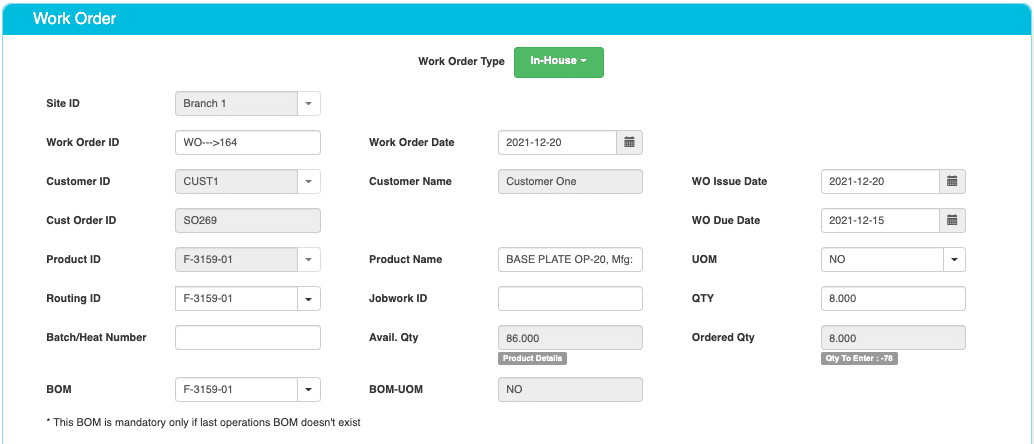

Below screen can be used to create a Manufacturing Work Order Manually.

- Select the ROUTING that suits for that WORK ORDER and for that FG.

- Based on the ROUTING ID, the process are added to the Work Order. You can still delete those predefined Process steps and add your own too.

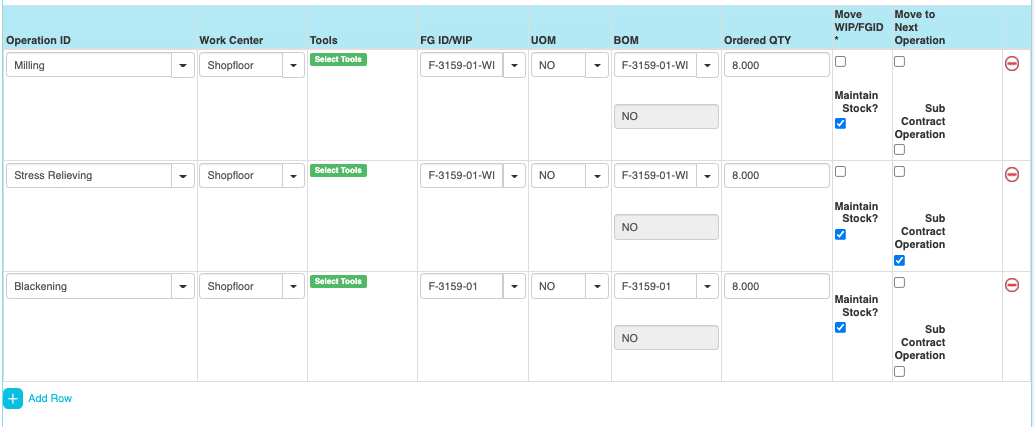

In the above, select the ROUTING ID, BOM ID for the Finished Goods and application will load the ROUTING ID and its steps thats pre-defined as below.

It shows the Operation ID, Work Centre where the work happens, FG ID and BOM thats used for this. You can change the conditions like Subcontracting Operation etc.

Work Order Field details are as below.

| No | Field ID | Field name | mandatory | Field description and how it helps? |

|---|---|---|---|---|

| 1. | Site ID | Branch ID to which this WO belongs | Yes | It gives the branch from where the work order is generated. |

| 2. | Work Order ID | Work Order Number | Yes | It gives a unique work order number for each Work Order. |

| 3. | Customer ID | Customer Identification Number | Yes | It gives a unique identification number to identify each of the customers. You have an option to convert the Sales Order to a Workorder. So the converted SO No is added here. |

| 4. | Customer | Customer Name | Yes | It gives the name of the particular customer to whom the sales has been done or in whose name the particular work order has been generated. |

| 5. | WO Issue Date | Work Order Commencement Date | Yes | The date on which the work commences for the particular Work Order. |

| 6. | WO Due Date | Worker Order Due Date | Yes | It gives the date by which the work has to be completed for the particular Work Order. |

| 7. | Cust Order ID | Customer order identification number | No | It gives the particular Customer Order ID number or linked Sales Order Number. |

| 8. | Product ID | Product ID | Yes | ID of Finished Goods that has to be produced. |

| 9. | Product Name | Name of the Product | Yes | Product name. |

| 10. | UOM | Unit of measure | Yes | Units of measurement. |

| 11. | Routing ID | Routing Identification Number | Yes | Each step of the working process is identified using a unique Routing identification number in the work flow process. Selecting the right Routing ID helps to load the steps that need to be followed to produce this FG and other subassemblies. |

| 12. | Job-Work ID | Job work number | No | In few cases, customer can have the Jobwork No assigned to the work order. This is mainly for tracking of the WO. |

| 13. | Quantity to Produce | Quantity produced | Yes | FG that needs to be produced. |

| 14. | BOM | BOM identification number | Yes | BOM ID for the Finished Goods. The Application will check this BOM ID to the last line of the WO Routing ID to ensure that it matches to each other. |

| 15. | BOM-UOM | Unit of Measurement for BOM | Yes | It is the UOM for the particular Bill Of Material (BOM) |

| 16. | Operation ID | Operation identification number | Yes | It is the unique identification number given to identify different operations in the work centre for that WorkOrder. |

| 17. | Work Centre ID | Work Centre Identification Number | Yes | Work center where this operation happens. |

| 18. | Tools ID | Tools Identification Number | Yes | It gives unique number to identify the appropriate tool which is being used for an operational activity. Tools are used mainly in Injection Molding or Press tools etc. It helps to capture, how much production done and when to do the Tool Maintenance work etc. |

| 19. | Finished Good ID/WIP | FG ID / Semi FG ID | Yes | It’s the FG or Semi FG that’s produced in this operations. |

| 20. | UOM | Unit of measurement | Yes | UOM ID. |

| 21. | BOM to be Used | Bill Of Material | Yes | It gives us which BOM is to be used to the particular Finished Goods to produce. |

| 22. | Time (Hrs) | Time required for producing the Finished Goods | Yes | Its gives us the total time required for producing the Finished Goods. It gives the operational time consumed for producing the Finished Good. |

| 23. | Move FG ID/WIP | Maintain Stock | No | Its always important to keep the Stock of the items that are produced. If its “Yes”, the stock is maintained and you need to enter FG ID and BOM related to the same. In Few cases, customer wants to capture the process and efforts, but not the physical stocks. Then set “NO”. |

| 24. | Move to Next Operation | Transfer to next Operational step | No | Normally, when a Semi FG is produced its sent to STORES DEPARTMENT and then we again receive it through MATERIAL REQUEST FORM (MRF) process. In case, you want this Semi FG to move to next Operation automatically, then select this. |

| 25 | Subcontract Operation | Set the value to Yes / NO | No | In case, you want to send this stage RMs to subcontractor to assemble and send back, the enable this flag = YES. Else keep it as it is. |

| 26. | Yes, want to generate child WO | In case, you want to create Multiple WO for each Routing Operations, then enable this flag = YES. So that you will have each Operation, one work order. Else keep it as it is. Settings to be done for each ROW with BOM IDRouting id.Set above 2 parameters into PRODUCT MASTER. |

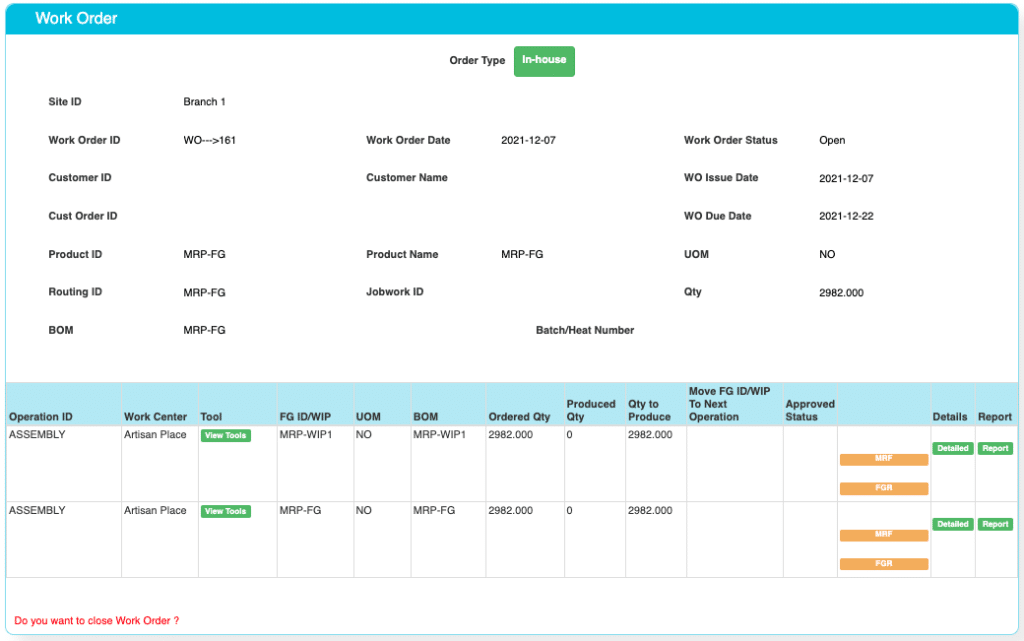

Created WO view

The Work Order shows the complete details at one Place.

- Operations to be handled.

- What are the Semi Finished goods expected from each operations.

- Any operation to be sent out for the Subcontracting or not?

- MRF – Materials request forms – Request RM from Stores to production locations.

- Report Production and receive the Finished goods.

A consolidated operations can be done at ONE PLACE.