What is Work Centre?

Work centre defines the Place or Machine where the work happens. For example, a Work Center could be a CNC Machine or Injection Molding or a Group of CNC Machines where the similar products are manufactured etc.

This definition helps to collect the information like what Products are manufactured in this Work center, which BOM to be used and What process are followed here etc.

Creating Work centre helps in linking the work in Work Orders. It helps to automate the process without much manual interventions.

We designed this process based on analysing Customer needs.

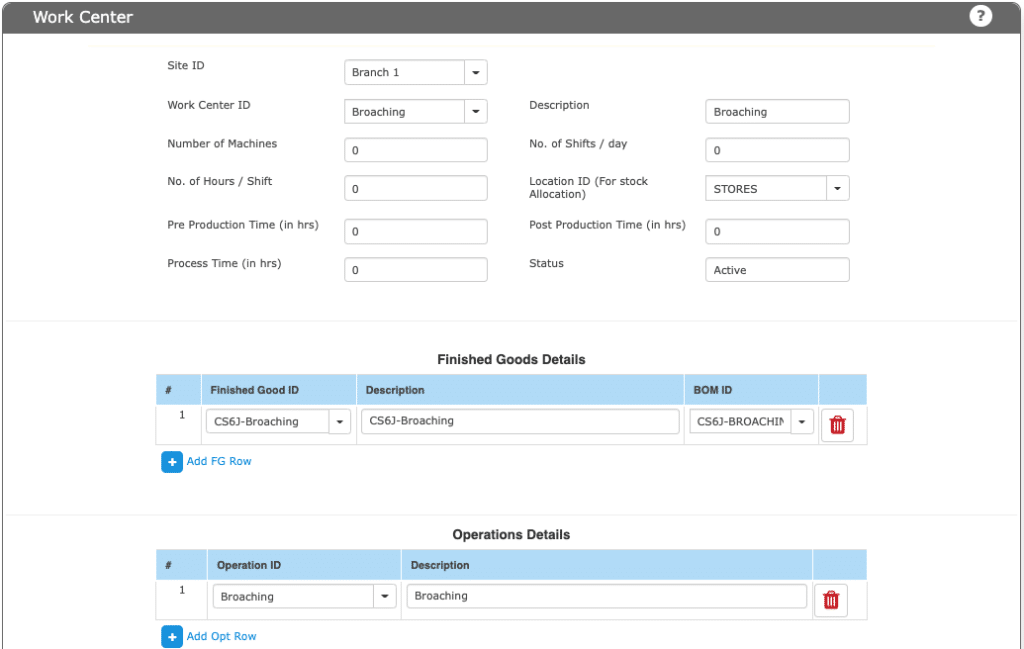

Work Centre Details

Work Centre is an input to ROUTING PROCESS with its Operation and Where the WORK HAPPENS.

Here you can multiple FGs, Operations and also the Tools that are used in this place. work center

Field Details.

| No. | Field ID | Field name | Mandatory | Field description and how it helps? |

|---|---|---|---|---|

| 1. | Work Centre ID | WC ID | Yes | It gives a unique identification number to each Work Centre. It could be a Machine or a Location where the work happens. |

| 2. | Number of Machines | Number of Machines | No | This gives the number of machines exists in a particular work centre. |

| 3. | Description | Description of the work in work centre | Yes | Work centre description |

| 4. | No. of Hours / Shift | No. of working hours per Shift | No | This is the number of working hours of the machines per shift. Shifts can be day/night. Note – This field is not used now. |

| 5. | No. of Shifts/ Day | No. of shifts in a Day | No | Total number of shifts in which the machines work in a day in the Work Centre. Note – This field is not used now. |

| 6. | Location ID (For stock Allocation) | Stock location | No | To identify the location where the stock is to be stored is provided by the location identification number. Here we link the WC ID to the Inventory Location ID. |

| 7. | Pre-Production Time (in hrs.) | Preparation Time of a machine before production activity begins | No | The time required to prepare the Work Center for the successful running of machine for the production. Example – Loading of Injection Molding Dies or Preparing the Machine with extra tools etc. Note – This field is not used now. |

| 8. | Post Production Time (in hrs.) | Post Production time needed to clear the machines. | No | The time required to clean the Machines after production. Example – Removing the Injection Molding Dies or removing the tools etc from CNC Machines. Note – This field is not used now. |

| 9. | Process Time (in hrs.) | Process time of a Machine. | No | The time required to produce an items. Note – This field is not used now. |

| 10. | Status | Status of the machinery | Yes | If the machine is working in production activity it is denoted by an Active / Inactive. |

| 11. | Finished Good ID | Finished goods ID | Yes | Finished Good ID that would be produced on this work center. |

| 12. | FG Description | Finished Good description | Yes | FG Name |

| 13. | BOM ID | BOM ID | Yes | Bill of Material ID that’s used in this work process. |

| 14. | Operation ID | Operation identification number | Yes | It is the unique identification number given to identify different operations in the work centre. |

| 15. | Description | Operation Description | Yes | It describes the operational activities of the machinery. |

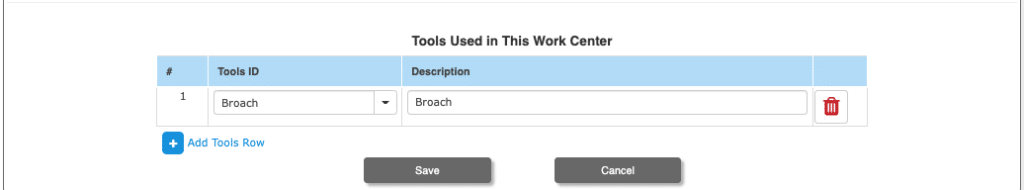

| 16. | Tools ID | Tools Identification Number | Yes | It gives unique number to identify the appropriate tool which is being used for an operational activity. |

| 17. | Description | Tool description | Yes | It describes the type of tool being used for a particular operation being done by the machinery. |

Once a Work Centre is created link this to a Routing Process. (Work flow Process / Steps for manufacturing)