What is Contract Manufacturing?

“Trust and Transparency is the Key for the success in the Contract Manufacturing”

Contract manufacturing is form of outsourcing where Business Owner can focus on his Sales and other strategies, while contract manufacturer is 100% responsible for the production and shipments of the items that are sold. This is a win-win for new product launchings and owners.

By this business model, the Raw Material or Semi Finished Goods are given to a Subcontractor to convert or assemble them into a Product or a Component. He would be paid for these services.

A contract manufacturing arrangement allows the parent company to utilize the manufacturing facilities of subcontractors to produce finished product, resulting in a reduction of manufacturing costs or do a private label manufacturing.

A contract manufacturer’s agreement can be beneficial for purchasing high-quality products with a standardized production process. This can lead to economies of scale and reduced costs of product design, as well as increased control over quality standards and monitoring processes.

It is important to consider and monitor key factors such as regulatory requirements, intellectual property protection, and the type of contract Production being entered into.

Pharmaceutical and food Production industries require strict quality management and cost control, necessitating reliable contract manufacturers for complex Finished products.

This is like an outsourcing of work, but it could also involve the product drop shipment to customers too. So the Contract manufacturers and Original equipment manufacturers needs to be clear on their Contract level.

International outsourcing or Subcontracting operations can be called as “Contract Manufacturing” with multiple types of contract manufacturing models.

But, there is no much difference between Subcontracting and Contract Manufacturing.

Subcontracting is the process, where the RM or Semi Finished Goods are supplied by the Business owner and the contractors would charge for the conversion or doing value addition.

However in contract manufacturing, the entire production with procuring the Raw Materials to finished goods is on the Contract manufacturers starting from sourcing of materials, vendor payments and all other challenges. So this leads to the Direct control lies with Contract manufacturing companies, but it also helps OEMs to avoid managing their own teams at remote places with huge language barriers.

In summary, Contract Production is a process where there is an agreement with business owner and a manufacturer to produce an agreed number of components and within an agreed timelines.

Contract manufacturing agreement needs to be stringent in case of OEM Manufacturers, private label Production with a production deadline where the production demands are huge.

This is a good business model like (where we have the IP Based licensing model)

- New 3D Printers

- New Plastic components

- New Electronics Circuit boards and testing

- Garments and textiles

- Bags, Leather shoes etc.

- Medicines, especially generic drugs etc.

What is Contract Manufacturing Definition?

A Business owner at USA found a new solution for the Production or Oil and Natural Gas segment. Now he has multiple challenges

- Someone to manufacture as per his specifications.

- No of pieces are less than 200.

- Ensure on-time and Quality deliveries.

- Cost should be cheaper than it might have been produced at USA.

- Where OEMs have a lack of control on the new technologies

- Ability to produce in large quantities based on short notice of production.

- Ability to manage all the production and legal complexity.

- Can not afford a Heavy machinery for the complex products design in his manufacturing industry.

- Entire manufacturing process time at contract manufacturers is less than in-house manufacturing process and Time needed.

- Need a smaller product volume with less product development costs and reduced cost of labor

- Ability to make a simple delivery arrangements with a strong Contract manufacturing agreements can make a difference.

- Need to build an entire supply chain management with advanced machinery and marketing strategies with new marketing team etc. So time is money.

He would approach a Contract Manufacturer to meet his demands and get the work outsourced. Today Mexico, India, Vietnam, China etc. are famous for Contract manufacturers and they contribute to the growth of the nation with new jobs and revenues

Benefits of Contract Manufacturing

- Helps to save money to the Business Owner – The advantage is that manufacturers have the existing machine setups, skilled people and have an expertise in producing a quality products at less cost.

- Less Labor costs and overheads to manage them is less.

- Opportunity to work with best in the industry to produce the quality products.

- Save Production time to see the real product – Helps to save time in not to setup companies, recruiting people, setting up machines and training etc. Idea can be tested at a small amount and see the results fast.

- Quick Entry to market with a MVP – Here the advantages is to generate the Product soon and test market before you launch the real product.

- Helps to focus on our strengths and take help of manufacturers to take his specialty of production, ability of supply chain etc.

- Offshore Production helps in Taxes, Overheads, Save in Energy, Employee costing etc.

- Streamline the business relationships across multiple vendors and these are integrated at the final Assembly Manufacturers.

- Supply chain can be integrated to meet customer demands.

Disadvantages of Contract Manufacturing

For every good work, there is an adverse effects too.

- It’s been shown that many times, the confidentiality of the Production is NO MORE A SECRET and it’s known to all. May be your competitor is fed all your trade secrets.

- Political problems could stop the interaction with the companies.

- Few contract manufacturers, may not be interested for the drop shipment across the world.

- Cultural differences including languages, practices and beliefs to handled efficiently.

- No control on the Production process or quality assurances.

- Finding the right contract manufactures is difficult

- If one Contract manufacturers does multiple contract work then his priority based on who pays more money would create problems to you

- Possible Human and Labor abuses to get a cost effective products. Nike’s contract manufacturers have been accused these type of practices and it affected Nike brand.

- Intercontinental supply chain, increase in material costs and other costs can impact your cost arbitrage itself.

How to select a Contract Manufacturers or Contract Maker?

Based on the experience and your business segment, you can decide on the below

- Can the manufacturer is ready to the Drop Shipment to the customer once the product is developer?

- Any quality certificates like ISO9000 etc?

- Company should be strong enough to handle the financial situation

- Reputation for quality and ontime delivery of products

- Good management that follows international laws and avoid child labor.

- Can able to scale up the production based on the short notice.

- Flexibility on Production and meet the deadlines.

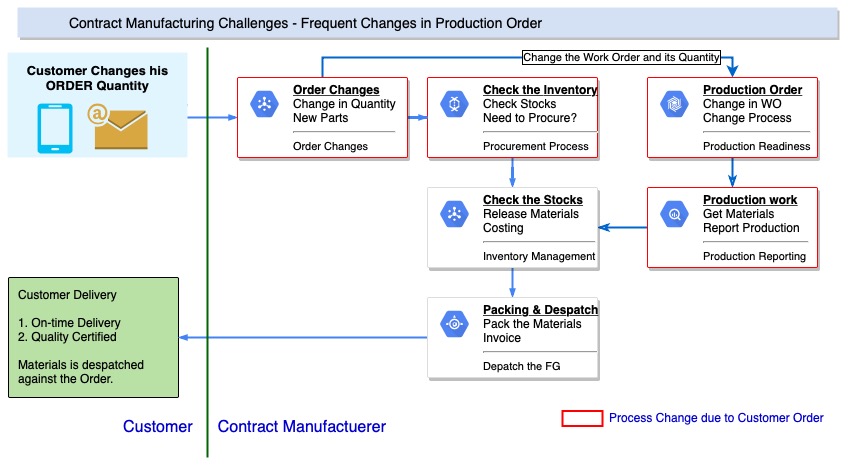

But Contract manufacturing is a challenge and how to manage?

You don’t need to change your Business Practices. We can match to the same.

Contract manufacturing is a competitive business and a contractor, who is with you may shift to someone else tomorrow. So you need to be on top of Production controls, Supply chain and logistics.

- Just because you have lowest cost contractors, doesn’t mean he can able to deliver on time. So you need to have an efficient process control to monitor his production, be aware of the quality process etc.

- May be you can have an office at his Production units to ensure the product quality.

- Cultural practices and what is in the contract mismatches. Its important to have a clear communication and Business Owner should have a mechanism to know the issues upfront.

FAQs on Contract Manufacturing

1. Who are Contract Manufacturers?

Contract manufacturers are companies that specialize in producing goods on behalf of another company, known as the client or contracting company. These manufacturers have the necessary production facilities, equipment, and expertise to manufacture products according to the client’s specifications, designs, and quality standards.

Contract manufacturing is commonly used when a company wants to focus on its core competencies, such as research and development and marketing, while outsourcing the production aspect to a specialized manufacturer. For example, Apple contracts with manufacturers like Foxconn to produce its iPhones.

2. What is Contract Manufacturing in International Business?

In international business, contract Production involves outsourcing the production of goods to a manufacturer located in a different country. This allows companies to take advantage of cost savings, specialized expertise, and access to new markets. For instance, a U.S.-based electronics company might contract with a Production facility in China to produce their products at a lower cost while leveraging China’s expertise in electronics Production.

3. Disadvantages of Subcontracting?

Subcontracting, a practice related to outsourcing, can have several disadvantages. First, loss of control over quality and production processes can lead to inconsistencies and product defects. Second, dependence on subcontractors can make a company vulnerable to supply chain disruptions if the subcontractor fails to deliver.

Third, communication and coordination challenges may arise due to geographical and cultural differences between the company and the subcontractor. Additionally, subcontracting might result in loss of proprietary information, as sharing detailed designs and processes is necessary. Lastly, if the subcontractor is not managed well, it can harm a company’s reputation if quality issues arise.

4. Advantages of International Contract Manufacturing

International contract manufacturing offers several benefits. It enables companies to tap into the expertise of manufacturers in different countries, often leading to higher product quality. Cost savings are also a significant advantage, as labor and production costs can be lower in certain regions. Access to new markets and distribution channels is facilitated, allowing companies to reach a broader customer base.

Moreover, companies can focus on their core competencies while leveraging the manufacturer’s capabilities. International contract manufacturing can also help companies respond to changes in demand quickly and efficiently by adjusting production volumes. For example, Nike uses international contract manufacturers to produce its sportswear, allowing it to offer a wide range of products to customers globally while benefiting from cost-effective production methods.

Importance of contract manufacturing

Every day, you should monitor the production, shipment, transportation, quality testing etc very closely. For that you need tools like ACTouch Manufacturing ERP that helps to link the Contract Manufacturers facility to you.

|